x

- Save Resources +

-

Products & Solutions

+

- Rebuilds & Performance

- Dewatering technology

- Machine cleaning and doctoring systems

- Vacuum control systems

- Fabric tensioning and guiding systems

- Consumables and wear parts

- Steam showers and rewetting systems

- Reel change systems

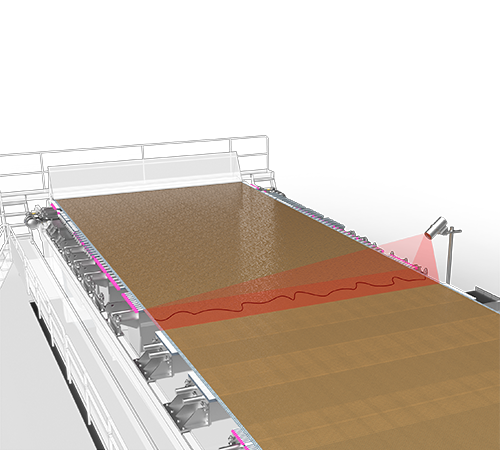

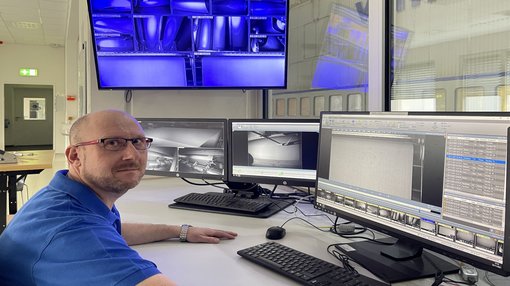

- Machine vision solutions

- Stock, additive and starch preparation

- Monitoring and control technology

- Metering systems

-

Safety

- safetyMASTER

- iSAFETY

back

- Edge and trim handling

- Tissue Solutions

- Services +

- About us +

- Careers +

IBS Austria GmbH

Hauptstraße 22

8833 Teufenbach-Katsch

Austria

Phone: +43 (0) 3582 8511

E-Mail: Send inquiry